Custom Tubular Panhard Bar - Del-Sphere Pivot Joints - Adjustable

Description

Videos

Replace the factory's weak, stamped steel, flexible panhard bar with one of our heavy duty set-ups! Allows for

centering the rear end after lowering. The best component for serious handling performance. Allows alignment of the rear for clearance when running larger tires.

Greatly increases rear's lateral stability.

This panhard bar can be used for any custom application. From street rods to 4x4 trucks, just tell us how you want it built and we'll build it!

Build Specifications:

- 1.25" x .095" wall DOM tubing

- Stronger, yet lighter than stock

- TIG welded 4130N chrome moly threaded tube adapters

- 3/4" Del-Sphere Pivot Joints

- Right hand and left hand threaded ends with integral wrench flats allow for easy on-car adjustment

- CNC machined through sleeve and steel spacers keep Del-Sphere ends perfectly centered inside of the vehicle mounting brackets

- Available powder coated in your choice of the above colors

Ordering Instructions:

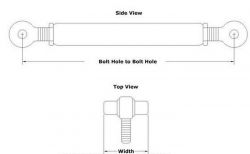

- Enter the bolt hole to bolt hole (C-C) length

- Enter the overall mounting width of End 1

- Select the mounting bolt diameter of End 1

- Enter the overall mounting width of End 2

- Select the mounting bolt diameter of End 2

- Choose mild steel DOM or 4130N Chrome Moly tubing

Schematic: Click on the small drawing above to view full size

schematic

4130N Upgrade: The ultimate in bullet-proof lightweight strength, 100% TIG welded 4130N chrome moly construction! Same as above, but constructed

entirely from 4130N chrome moly tubing.

The panhard bar bushings have a significant impact on your vehicle's ride, comfort, handling, acceleration, noise and vibration. When the vehicle leans (rolls) in a turn, one side of the chassis moves up relative to the rear axle and the other side moves down. The panhard bar must twist to allow for the axle to articulate, this causes the panhard bar bushings to bind. If this bind becomes excessive, it will raise the rear wheel rate and produce sudden and uncontrolled changes in handling such as snap oversteer.

The factory minimizes this suspension bind by using compliant rubber bushings. These soft bushings help accommodate the necessary motion of the panhard bar during body roll. However, the rubber bushings do not provide much in the way of positive lateral support.

It is common to replace the stock rubber panhard bar bushings with polyurethane bushings to resolve the shortcomings

of the factory's soft rubber bushings. The downside of polyurethane bushings is they prevent the necessary movement of the panhard bar during body roll, which in turn

produces significant binding in the suspension when the vehicle is cornering. The polyurethane bushings also place high stresses on the panhard bar mounts on the

vehicle. Polyurethane bushed panhard bars do not allow for rotation of the panhard bar during cornering because of the stiffness of the bushings.

Del-Sphere Pivot Joints:

The Spohn Performance Del-Sphere pivot joint solves the shortcomings of the factory rubber and aftermarket polyurethane bushings. Our Del-Sphere pivot joint incorporates a spherical ball which is surrounded by delrin bushing cups. This combination allows the panhard bar to articulate like a spherical rod end (28 degrees of available rotation) during cornering but the spherical ball does not allow the bushing to deflect. Therefore the panhard bar remains completely bind free like a spherical rod end during cornering for predictable traction in the corners.

Think of the Del-Sphere pivot joint as a Delrin bushed spherical rod end. After over a year of R&D testing here at Spohn Performance on a streetable spherical joint the Del-Sphere pivot joint is the final result. Designed and manufactured exclusively by Spohn Performance, we have taken street suspension performance to the next level. Our Del-Sphere pivot joint features a one piece forged and heat treated chrome moly housing, a heat treated and chrome plated chrome moly spherical ball, Delrin bushing cups, heat treated retainer washer and snap ring, heat treated and chrome plated chrome moly threaded adjuster ring, an external grease fitting and a beautiful silver zinc plated housing finish.

The Delrin bushing cups absorb shock and road noise so you get the quiet and smooth ride of a bushing as well as 28

degrees of rotation! Our Del-Sphere pivot joints will always ship to you fully assembled, however, we also offer an optional adjusting tool that will allow you to do

two things. First, you can disassemble the Del-Sphere pivot joint for cleaning, inspection, etc. Second, you can adjust the amount of friction on the spherical ball.

Do you want a very low friction pivot joint or a very tight pivot joint? It's up to you, the amount of tension can be easily adjusted by using our optional adjustment

tool to

tighten or loosen the end retainer ring. What that also means is if over time and miles the tolerances open up you can simply re-adjust the retainer ring and have your

pivot joint as tight as it was the day it was brand new. We doubt you'll ever need to replace the Delrin bushing cups, but they certainly can be. Unlike a spherical

rod end, the Del-Sphere pivot joint is 100% rebuildable.

What is Delrin, and why did you choose to use it? Delrin is an acetal homopolymer made by DuPont. It

is characterized as having an excellent combination of physical properties that make it suitable for numerous applications. With extremely low moisture absorption and

a low coefficient of friction (self-lubricating), Delrin is uniquely tailored for wear applications in high humidity or moisture environments. Delrin will maintain

constant physical properties under high moisture conditions and out-perform nylon or polyurethane under these conditions. Delrin has a 10,000 psi tensile strength and

a 120 Rockwell Hardness rating making it ideal for our Del-Sphere application.